|

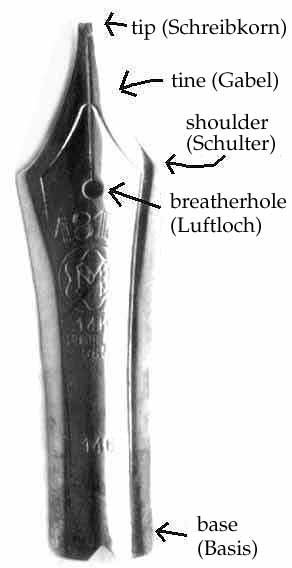

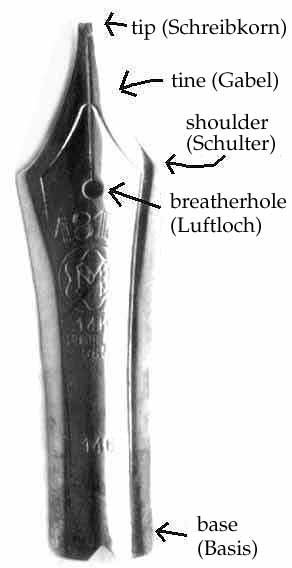

First, some nib terms, so you won't get bogged down in technical jargon: The Tip is, as the name would

imply, the tip of the nib, that portion that actually contacts the paper. Usually, there will be a pellet

of Iridium welded to the gold or steel, although on some less expensive steel nibs, this is absent. The Tines

are those portions of the nib that slopes up to the tip, separated by the slit cut in the nib. The Shoulder

is the widest portion of the nib. The Breather Hole is cut into the nib at the end of the slit. This is

not present on all nibs, modern Watermans, for instance, do without it, but virtually all vintage nibs have this

feature. The Base is the bottom of the nib.

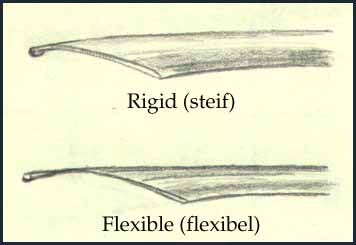

Let's begin with a look at what makes a nib a "real" flex nib. The word real is in quotes because

there is a lot of debate over flexibility in nibs, and whether or not certain nibs should be called flexible. To

begin with, all nibs are flexible, to a degree. Whether made of steel, gold, or some other metal, the tines will

spread apart as pressure is applied. However, a flex nib has a much greater degree of flexibility in the tines

than a rigid nib.

There are a lot of factors that contribute to this flexibility. One of the first things you might note when

looking at a flex nib next to a rigid nib is the length of the tines. As you can see in the picture below, the

flex nib, this one from an early Boston Safety pen, has a narrower shape, with proportionally longer tines than

the far more rigid Sheaffer Lifetime nib. The longer the tines are, the more flexible they will be, if all other

things are equal.

Of course, all other things will likely not be equal! Another feature common to the construction of flexible

nibs is their thickness. The more flexible the nib, the thinner it will be. In some cases, this will be a matter

of degree, and it can be hard to tell the difference, in others, it can be quite obvious. Just try comparing the

thickness of an early Sheaffer Lifetime nib to a Waterman #6! The Sheaffer is just under 1/32 of an inch thick,

while the Waterman is under half that. Guess which one is flexible......

|