|

WHAT TO LOOK FOR WHEN BUYING

Okay, so Snorkels are still around, and fairly easy to get, and you want to buy one. What are the pitfalls?

First off the complexity of the filling system, and the fact that even in the 1950s people were becoming less

"literate" in the care and feeding of fountain pens, means that the likelihood of finding a pen still

in working condition is rather slight, though by no means impossible. For example, two of the Snorkels in my own

collection that I coincidentally paid the least for, happened to be pens that worked and filled "as found".

But overall, any used Snorkel pen should be assumed to require some work to get it going again. If you are not

versed in doing this yourself, you’ll need to figure restoration costs in your purchase price considerations. (note

that Snorkel repairs are covered by Nathan Tardif in the next segment of this article).

Snorkel pens, like their earlier brethren the Touchdown models (and further back, models from companies such

as Chilton) are pneumatic fillers—that is, they use the compression of air as the means by which to compress their

rubber ink sacs, rather than direct pressure applied by a lever or button system. O-rings and sealing gaskets,

with an associated pressure-relief groove in the plunger tube, enables the pen to manage this air compression and

its subsequent release. Hence, the proper operation of the Snorkel pens is primarily a function of controlling

air leaks that would otherwise inhibit the proper compression of the ink sac.

|

One telltale way to determine the health of the pen’s filling system is to extend the snorkel tube from the

feed, and work the plunger with the blind cap. A pen with good seals should give off a slight "whoosh"

sound from its back end when the plunger is depressed, which means that compressed air inside the barrel is being

released as designed, rather than prematurely from leaking or hardened seals.

However, even if the seals are good, that is no guarantee that a pen will fill. This still depends on the condition

of the ink sac, which often has become hardened over the years within its steel sac protector tube, hence requiring

replacement.

If no sound is heard, and the plunger tube either moves too freely (or conversely with too much resistance),

that is usually a sign that the O-ring that seals the barrel against the plunger tube has gone bad, and will need

replacement. Leakage is also a common problem in the feed end, where a section gasket must provide an air and fluid

tight seal around the snorkel tube when it is extended.

A Snorkel in particularly bad internal condition is one where it is all but impossible to extend either the

snorkel tube or the plunger tube. This is a sign of seizure due to fluid seepage into the barrel and subsequent

rusting/gunking up of interior metal components (the propelling spring is especially vulnerable to unwanted moisture).

While it is possible to clean up and restore parts damaged in this manner, the ready availability of spare Snorkel

parts should give you the option of replacement as well.

If the snorkel tube is present, unbent, and otherwise not deformed, and the plunger tube extends, then you can

try to unscrew the section from the barrel to examine the condition of the internal parts. Sometimes the presence

of a sealing shellac or other material from the factory (or a previous repair) will make this difficult, but I

usually find that most pens will open without heating. Soaking is not so readily recommended unless absolutely

necessary, so as to prevent the possibility of any further moisture intrusion that could damage internal parts.

Finally, there is the problem of cracks. Common places where they occur are in the blind cap and back end of

the barrel (sometimes due to excessive force applied there when the filling mechanism became cranky) and in the

front gripping section, where the nib assembly screws into it. Any of these will cause air leaks that prevent proper

filling action, even if the rubber seals are good. Air leaks are also common from the threads at the barrel/section

joint—something easily remedied by a sealant material during final reassembly. Cracks in these components are not

easily repaired, though they can be done in a pinch, using a good plastic solvent (cosmetic touchups will probably

be necessary afterward). Still, the best bet is replacement of cracked pieces from a "parts" Snorkel.

Another common place for cracks is in the cap, usually starting from the clip mounting area. Cap cracks don’t

affect the operation or filling of the pen, but of course aren’t desirable. A loose clip that moves from side to

side can be a giveaway to an otherwise nearly invisible crack that lies underneath the clip. Otherwise, cracks

can be seen coming out at an angle from the attachment point. Often, the clip’s spring action will not be badly

affected, though any subsequent tension on the clip may cause cracks to extend. Nathan Tardif will cover cap repairs

(as well as filling system repairs) in the next section, so it is up to the buyer to determine whether a cracked

cap should be repaired or replaced.

If these pitfalls can be avoided, and with careful restoration work, a Snorkel can be a very trouble free pen.

The fact that they can still be bought for bargain prices compared to other more glamorous, but often crankier

vintage pens should make them recipients of much greater respect. But if not, then at least those of us that still

appreciate them can have even more of these nifty pens to ourselves!

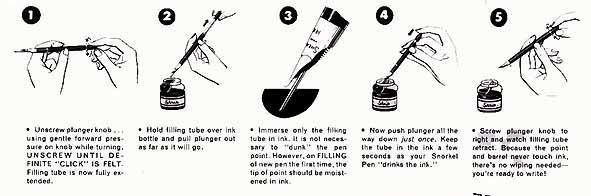

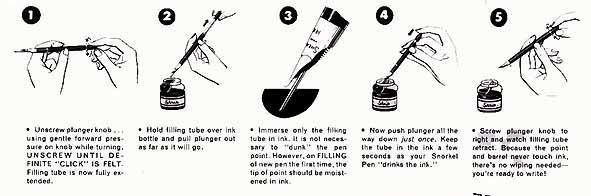

(from an original instruction sheet included with every Snorkel box)

NEXT PAGE